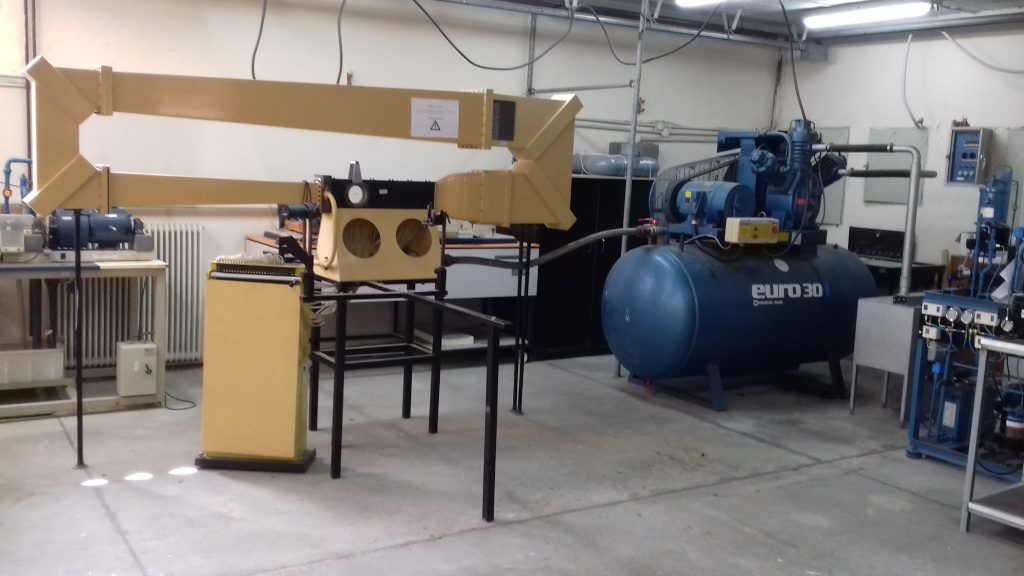

Use in Fluid Dynamics II lab.

An intermittent operation, induction-type supersonic wind tunnel for investigations into subsonic and supersonic flow.

This includes tests on the flow around two-dimensional models at subsonic and supersonic air speeds. A compressed air supply induces a flow in the working section of the wind tunnel. This gives a less turbulent and more stable flow for accurate results and comparison with theory. The optional compressed air supply includes filters and air dryers to give a dust-free and dry air source needed for good results.

Students use a delivery valve to allow compressed air to enter the wind tunnel. The wind tunnel includes two analogue pressure gauges. One measures the compressed air pressure available from the supply (for reference); the other measures the pressure delivered to the wind tunnel.

The working section of the wind tunnel is a convergentdivergent nozzle with a removable top part (‘liner’). The shape of the liner controls the maximum air velocity at the divergent part of the working section. Included are three different liners.

High optical-quality glass windows (‘portals’) are at each side of the divergent part of the working section. The portals allow students to use the optional Schlieren Apparatus. This allows display and recording of images of pressure waves around two-dimensional models.

Included is a set of two-dimensional models. These mount between the portals inside the working section. Students can adjust the angle of the models. An encoder electronically measures the model angle.

Spaced at precise intervals along the working section of the wind tunnel are pressure tappings. Two extra tappings connect to one of the models when in use. A 24-way pressure display included connects to all the pressure tappings. It displays the pressures for recording and calculations of pressure ratios and Mach numbers.